Operating Deflection Shape Analysis using Alta Solutions Analyzer

- RC

- May 22, 2025

- 3 min read

Operating Deflection Shape (ODS) analysis is a highly effective technique for diagnosing and identifying the root causes of structural vibration issues that are often undetectable in routine vibration data collection. Unlike traditional methods that focus on individual measurement points, ODS allows engineers to visualize the dynamic deformation pattern of an entire structure in real-time, providing a comprehensive understanding of its vibrational behavior.

This analysis is conducted while the machinery and its associated structures are under normal operating conditions, ensuring that the observed vibration patterns accurately reflect real-world performance. By capturing the actual operational response of the system, ODS helps pinpoint structural weaknesses, resonance problems, flexible support, looseness, or misalignments that may otherwise go unnoticed, making it an invaluable tool for predictive maintenance and troubleshooting.

Instruments Required for ODS Measurement and Analysis

To perform ODS analysis, the following instrumentation is typically required:

Multi-Channel Vibration Analyzer

A 2- or 4-channel analyzer is used, depending on whether 2D or 3D motion analysis is required.

Single-Axis Vibration Sensor (Reference Sensor)

A single-axis accelerometer is typically fixed at a reference point to ensure consistent phase and amplitude comparison across all measurements.

Triaxial Vibration Sensor (Roving Sensor)

A triaxial accelerometer is used as a roving sensor to capture vibration data at multiple points on the structure.

For 2D motion analysis (e.g., beams or floor planes), a single-axis accelerometer may suffice.

Trigger Signal (Conditional Requirement)

Some data acquisition systems require an external trigger signal to initiate measurements, while others automatically record data once the signal stabilizes.

Vibration Data Collection Software

Interfaces with the analyzer to control data acquisition and define degrees of freedom (DOF) for each measurement point.

Allows real-time monitoring of vibration data via time waveforms, spectra, or transfer functions (FRFs).

Supports data export in standard formats such as Universal File Format (UFF) or ME’scope VES format.

Data Processing & Analysis Software (e.g., ME’scope VES)

Used for post-processing, including:

Modal parameter extraction (curve fitting)

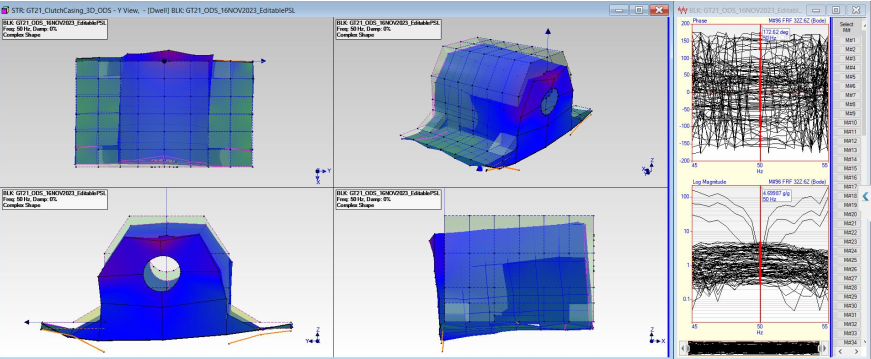

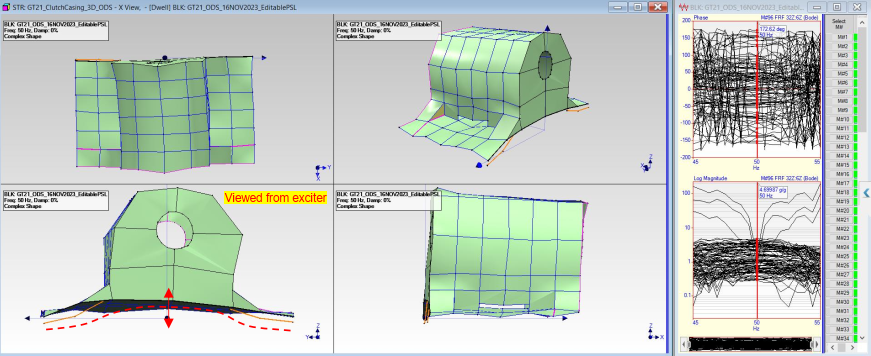

3D animation of structural deflection shapes

Physical modeling of the structure

Simulation of structural modifications (what-if scenarios)

Report generation for diagnostics and decision-making

Alta Solutions (AS) Measurement System: AS1250FE Analyzer & AS410 Software

The AS1250FE analyzer and AS410 companion software provide a streamlined, user-friendly solution for ODS analysis. The compact and lightweight AS1250FE features 8+2 channels in a small chassis—more than sufficient for typical ODS applications. Its battery-powered operation and built-in IEPE (Integrated Electronic Piezo-Electric) excitation for all channels make it ideal for field measurements, eliminating the need for external power supplies or signal conditioners.

The AS410 software offers advanced capabilities for real-time monitoring and analysis:

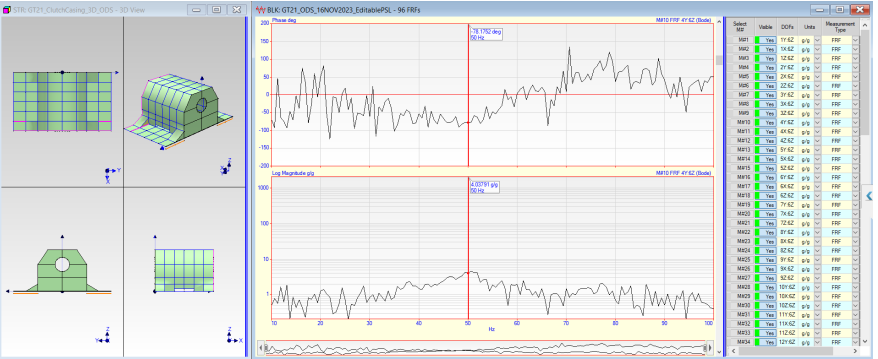

Simultaneous display of reference/roving points, degrees of freedom (DOFs), and FRF (Frequency Response Function) data.

Live visualization of time waveforms, spectra, and transfer functions during data collection.

Raw data storage for each measurement point, enabling post-processing, corrections, or further analysis.

Seamless compatibility with ME’scope VES for advanced modal analysis and reporting.

With an intuitive interface and efficient workflow, the AS system simplifies ODS data acquisition and analysis, making it an excellent choice for field diagnostics and structural troubleshooting.

Additional Considerations for ODS Analysis

Measurement Planning & Best Practices

Optimal Sensor Placement – Strategically position reference sensors near excitation sources or rigid structures to minimize noise.

Sampling Parameters – Ensure proper frequency resolution (Δf) and Nyquist criteria are met for accurate FRF calculations.

Averaging & Coherence – Use multiple averages and monitor coherence to improve signal-to-noise ratio.

Advantages of the AS1250FE & AS410 System

Portability – Lightweight design and battery operation enable easy measurements in hard-to-access locations (e.g., offshore platforms, tall structures).

Scalability (pre-configured system, 10 to 40 channels) – The 8+2 (10) channels configuration supports both small (e.g., pumps, beams) and large structures (e.g., bridges, turbines).

Automation Features – Auto-range settings, real-time alerts for clipping/distortion, and batch processing for repetitive tests.

Advanced Applications with third party software

Structural Modifications Simulation – Use ME’scope VES integration to predict vibration responses after design changes (e.g., adding stiffeners, dampers).

Correlation with FEA – Validate finite element models by comparing simulated vs. experimental ODS results.

Troubleshooting Complex Issues – Diagnose problems like loose bolts, resonance, or fluid-structure interaction (e.g., pipe vibrations).

Limitations & Mitigations

Environmental Noise – In high-noise environments, use windowing techniques or transient excitation (e.g., impact hammer) instead of operational data.

Nonlinearities – ODS assumes linear behavior; for nonlinear systems (e.g., cracked structures), consider complementary techniques like modal testing.

Reporting & Documentation

Generate animated ODS plots with overlay diagrams (e.g., deflection shapes at critical frequencies).

Export results to universal formats (UFF, CSV) for integration with third-party tools like MATLAB** or Python.

Combining the portability of the AS1250FE analyzer with the analytical power of AS410 software, Alta Solutions delivers a turnkey system for efficient ODS analysis. By adhering to best practices in measurement planning and leveraging advanced features like real-time FRF visualization and FEA correlation, engineers can rapidly diagnose vibration issues and optimize structural performance—even in challenging field environments.

*ME’scope VES is a registered trademark of Vibrant Technology, Inc., USA.

**MATLAB is a registered trademark of The Mathworks, Inc.

Comments